How To Adjust Fuel Pressure Regulator

How to Hook Upward Fuel Pressure Regulator

Fuel force per unit area regulators are an essential role of your car'south fuel organization. They assistance ensure that the correct corporeality of fuel is delivered to the engine nether all conditions. If your automobile is experiencing problems with dispatch, poor fuel economy, or black smoke from the frazzle, a faulty fuel force per unit area regulator may be to blame.

If you're looking to install a fuel pressure regulator on your vehicle, there are a few things you lot need to know before getting started. In this article, we'll walk yous through how a fuel pressure regulator works and provide some tips on how to claw up fuel pressure regulator. And then, whether you're a novice mechanic or just looking to add this upgrade to your car, read on for all the data you demand!

What is a Fuel Pressure Regulator

A fuel pressure regulator is a device that keeps the fuel line pressure at an optimum level. It has a certain pressure threshold which information technology will not let the fuel increase or decrease from, no affair how much or how little fuel y'all are sending through.

Fuel Pressure Regulators are located on the back of about cars' engines. They are generally black and silver and take the class of a cylindrical box with several tubes coming out of the sides. In that location volition be a fuel line connected to information technology and an electrical plug and then one other tube connected to nothing.

What is the Purpose of a Fuel Pressure Regulator

Fuel force per unit area regulators benefit the vehicle owner in ii ways. Get-go, information technology is programmed into mod vehicles to command backlog fuel pressure inside the engine so that it runs with about six psi of pressure level under most conditions. Second, it will release excess fuel when needed to have a sufficient volume of fuel inside the engine. This prevents stalling or not starting, which can impairment the motorcar.

ten Ways on How to Hook Upward Fuel Pressure Regulator

i. Remove Old Regulator from Fuel Track:

Unscrew the three force per unit area regulator mounting bolts and remove them from the fuel runway. Next, remove the fuel rail finish plug and so clean off any sealant on the opening where the regulator was at.

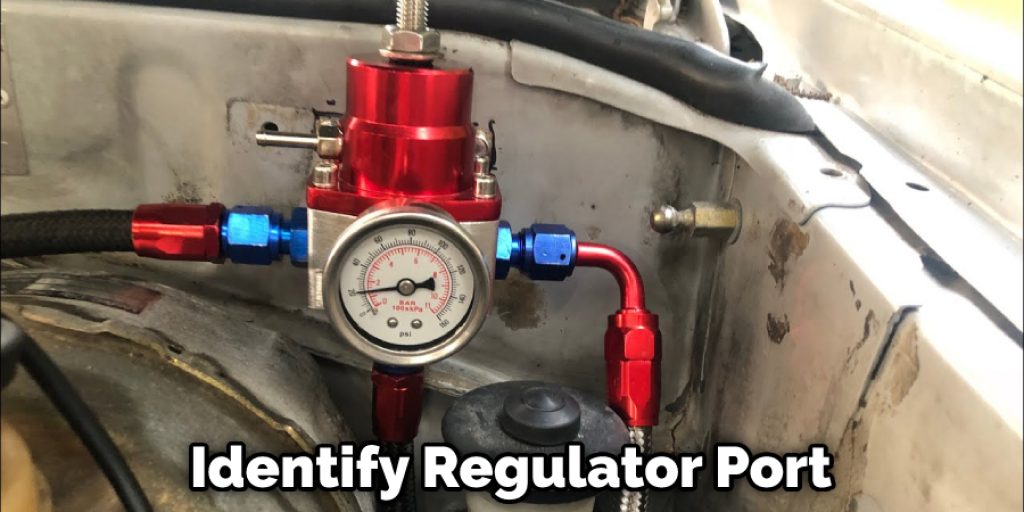

2. Identify Regulator Inlet and Outlet Ports:

Identify which port your regulator inlet line is, which will have a banjo bolt fitting. Then place which port is your regulator outlet line, which volition have a plastic tube running from the fuel rail to the new regulator.

3. Acquire Fuel Inlet Hose:

Acquire a high force per unit area/high volume hose section that will reach from the fuel runway outlet port on the new regulator to the fuel supply line where you lot tin attach the diesel fuel supply line.

4. Install New Regulator to Rails:

Install your new regulator to the rails using the three bolts; tighten them down without over-tightening to ensure there is no leak between regulator and rail. Now install both metal banjo-to-hose fittings, one on the inlet port and one on the outlet.

5. Adjust Fuel Pressure:

Follow the set-up steps that came with your new fuel force per unit area regulator. In one case you have turned the adjusting screw clockwise, turn off the engine, bank check for leaks between hose fittings, and ensure that no air is leaking into or out of the regulator inlet line. If there is a leak, turn the adjuster counterclockwise until no air is seen.

6. Install New Fuel Line:

Remove the old line from the fuel rail and install a new high-pressure hose to the regulator outlet port using same clamps as your current lines have been using. Utilise Teflon tape on all banjo bolt fittings for a snug fit, and use manus Teflon pliers to tighten clamps.

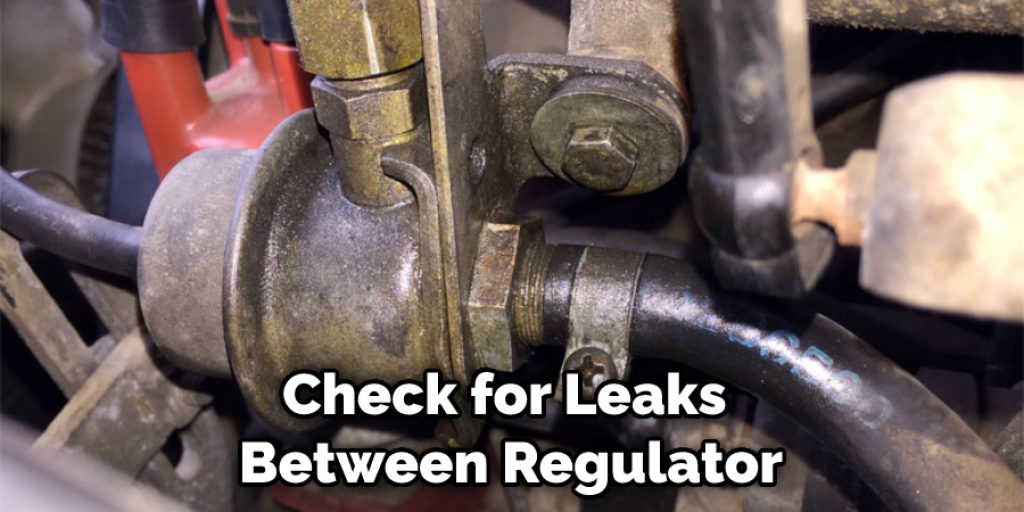

7. Check For Leaks:

Now bank check for leaks between regulator, fuel line fittings, and fuel pump cease plug where you removed this one-time piece of hardware and clean off whatsoever remaining sealant. The leaks should exist minimal simply if needed, use a wrench on the regulator adjusting spiral to plow it clockwise until the leak is stopped.

eight. Starting time Engine:

Starting time your engine and picket for leaks between regulator fittings, adjuster, and fuel line fitting by turning the pressure adjuster counterclockwise to eliminate these pocket-size leaks. Annotation that a small amount of air may exist nowadays in lines, only this volition right itself in a short fourth dimension.

ix. Thread New Regulator Inlet Lines:

Take your injector-rated fuel hose and route it from the regulator inlet port to the banjo plumbing fixtures on the end of the rails going out to the engine via a hinge coupling, ensuring that you have the tightest fit possible. Utilise two hose clamps on the banjo fitting and Teflon record for all fittings.

10. Open a Valve Downstream of the Regulator:

Open up a valve downstream of your fuel pressure level regulator to connect a gauge to the line and check for over-pressure. You can use this regulator to control the pressure that enters the track. Your new fuel pressure regulator should exist adjusted co-ordinate to any directions for your item regulator.

The manufacturer'southward instructions should be followed exactly, as the parts are designed for a specific range of input/output pressures manufactured by its specifications to ensure proper performance.

Things to Consider When Hooking Upwards Fuel Pressure Regulator

1. Fuel Force per unit area Must Exist Fix Correctly:

The force per unit area you set up your fuel pressure regulator to is based on the vehicle'south needs. For example, some functioning cars require higher than normal pressures, while others need lower than normal ones.

Consult a manual or ask a dealer what the specific requirements are for your automobile. For example, in terms of reliability, an engine tin run with the wrong fuel pressure, merely it will skip and sputter; lower than normal pressure level may starve the engine of fuel, while higher than normal is just wasteful.

2. Fuel Force per unit area Regulator Must Be Adjusted:

The regulator has a pocket-sized screw that adjusts the pressure within the regulator. It is better to aim low, then increase as needed rather than having besides much pressure and wasting fuel. If the regulator is adjusted incorrectly, information technology will cause problems.

3. Fuel Pressure Regulator May Leak:

The fuel pressure level regulator is an important part of your car's engine management arrangement; it maintains the correct fuel force per unit area nether many dissimilar driving conditions. However, fifty-fifty if y'all get everything connected perfectly, there is a risk that your fuel pressure regulator will leak, and y'all'll find yourself in the aforementioned position in a few months.

4. Pressure Gauge:

Y'all need to know what your fuel force per unit area is at whatsoever given fourth dimension to adjust information technology with the regulator knob appropriately. Purchase a approximate that connects straight to the fuel rail with hose clamps.

5. Inline Fuel Filter:

The last thing yous desire is debris from a corroded or collapsed fuel line clogging up your pressure regulator and causing even more than problems. But, of course, this will but happen if the regulator breaks loose from fuel pressure, so make sure to secure it correctly both with its strap and in a vise-grip to the rails.

vi. New Fuel Lines:

The auto parts store will recommend new fuel lines for your machine when you ask them how to hook up a fuel force per unit area regulator. Instead, they'll suggest an overpriced plastic line like the corrugated rubber hose that is already in place on most cars.

The truth is that in that location's no need to replace the stock line unless it has seriously deteriorated. If there's a expert section that yous tin cut out and replace, go ahead and get a new hose. If it is severely damaged, but cut off the bad office and proceed going.

7. Lubricating O-Ring:

The one other thing to recollect about hooking up the fuel pressure regulators is to lubricate the O-band connector. The best manner to do this is to pressurize the regulator with air and spray some WD40 on the connector. Allow the regulator cool before you take the pressure off or disconnect it.

How Does a Fuel Pressure level Regulator Work

A fuel pressure regulator works equally a safety mechanism to protect the engine from running also high of fuel pressure, damaging or destroying engine components.

It is typically mounted on the fuel rail with a rubber or metallic tube leading into information technology that goes direct into the intake manifold. A jump-loaded diaphragm directs excess fuel back into the fuel tank when fuel pressure exceeds what the engine can run safely.

Determination

If you're looking to increment your fuel pressure and improve your engine'south performance, then a fuel pressure regulator is the best way to practise it. Installing one of these regulators is an easy process that tin can be washed in only a few minutes, and it can make a big difference in how your auto runs.

The first footstep is to remove the old regulator from your vehicle. This is usually done by unscrewing it from the intake manifold or carburetor.

Once information technology's off, look at it to see how information technology attaches. The pressure level regulator is the device on most fuel-injected cars that regulates the fuel pressure within the fuel rail. We hope this article has helped you acquire more than about how to hook upwards fuel pressure regulator and shown yous how easy they are to install. Thank you for reading!

Source: https://diyquickly.com/how-to-hook-up-fuel-pressure-regulator/

0 Response to "How To Adjust Fuel Pressure Regulator"

Post a Comment